Ukraine

PE Pipe Extrusion Line

The extrusion line operates reliably and meets our production requirements for PE pipes.

PE Pipe Extrusion Line

PE line making machine

Drainage pipe Extruder

20-110mm HDPE pipe extrusion line

Highlights

Stable extrusion performance for PE pipe production

Accurate control of pipe diameter and wall thickness

Smooth coordination between upstream and downstream units

Suitable for long-term continuous operation

Tailored Solution

01.

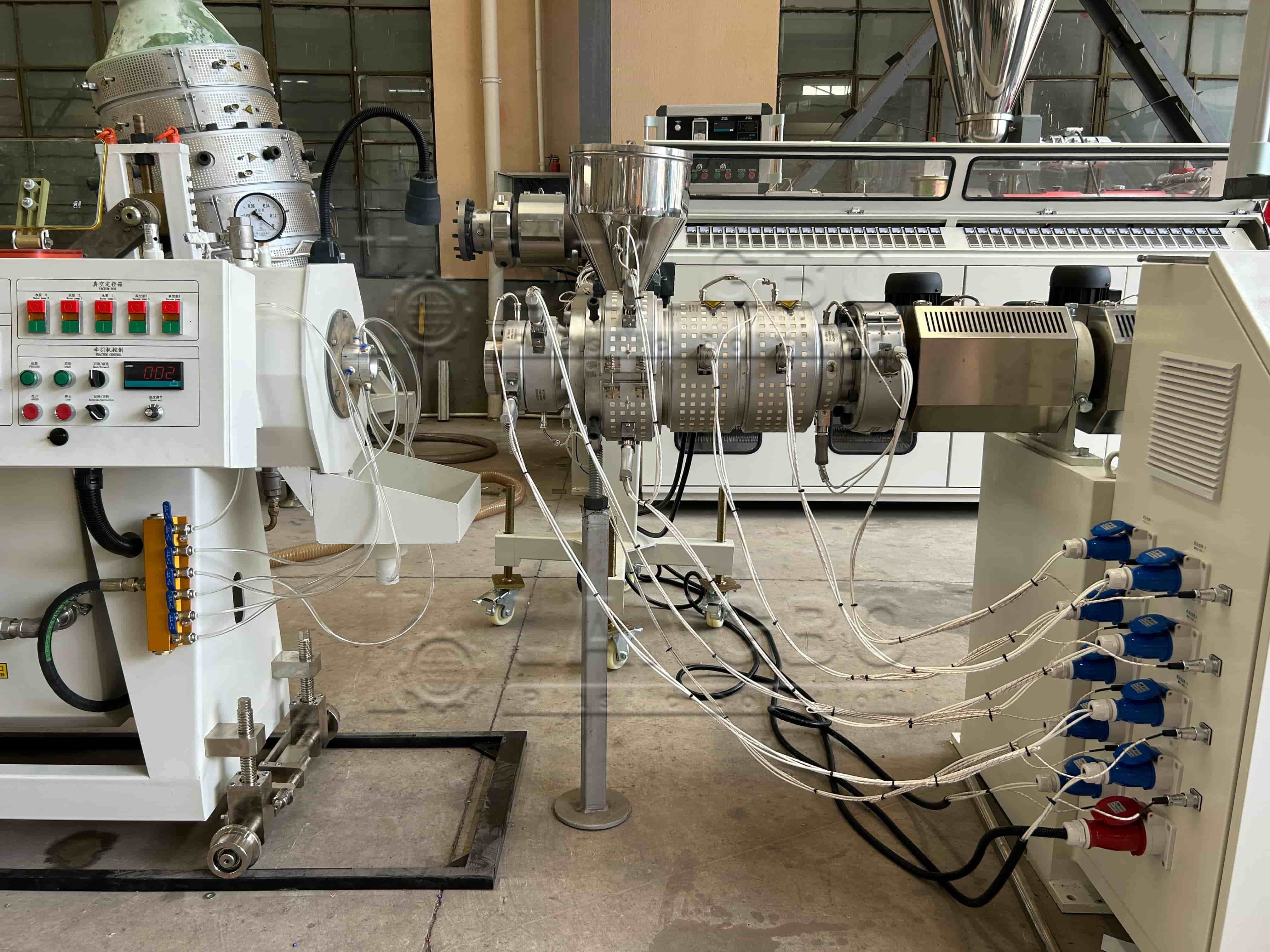

Extruder

A single screw extruder was selected for PE pipe production,ensuring stable melting, uniform material flow, and consistent output during continuous production.

02.

Mould

The mould was selected according to the customer’s pipe diameter range and pressure class. Optimized flow channels support uniform wall thickness and steady extrusion.

03.

Vacuum Calibration

A vacuum calibration was applied to maintain accurate pipe sizing and roundness. Adjustable vacuum and cooling settings allow stable processing of different pipe specifications.

04.

Haul-off Unit

The haul-off unit provides synchronized pulling force with extrusion speed, ensuring stable pipe movement without deformation or surface damage.

05.

Cutting Unit

A planetary cutting system was applied to the PE pipe extrusion line. The cutter follows the pipe movement during cutting, ensuring smooth, burr-free pipe ends without stopping the extrusion process. This cutting method is suitable for continuous production and maintains stable pipe length accuracy.