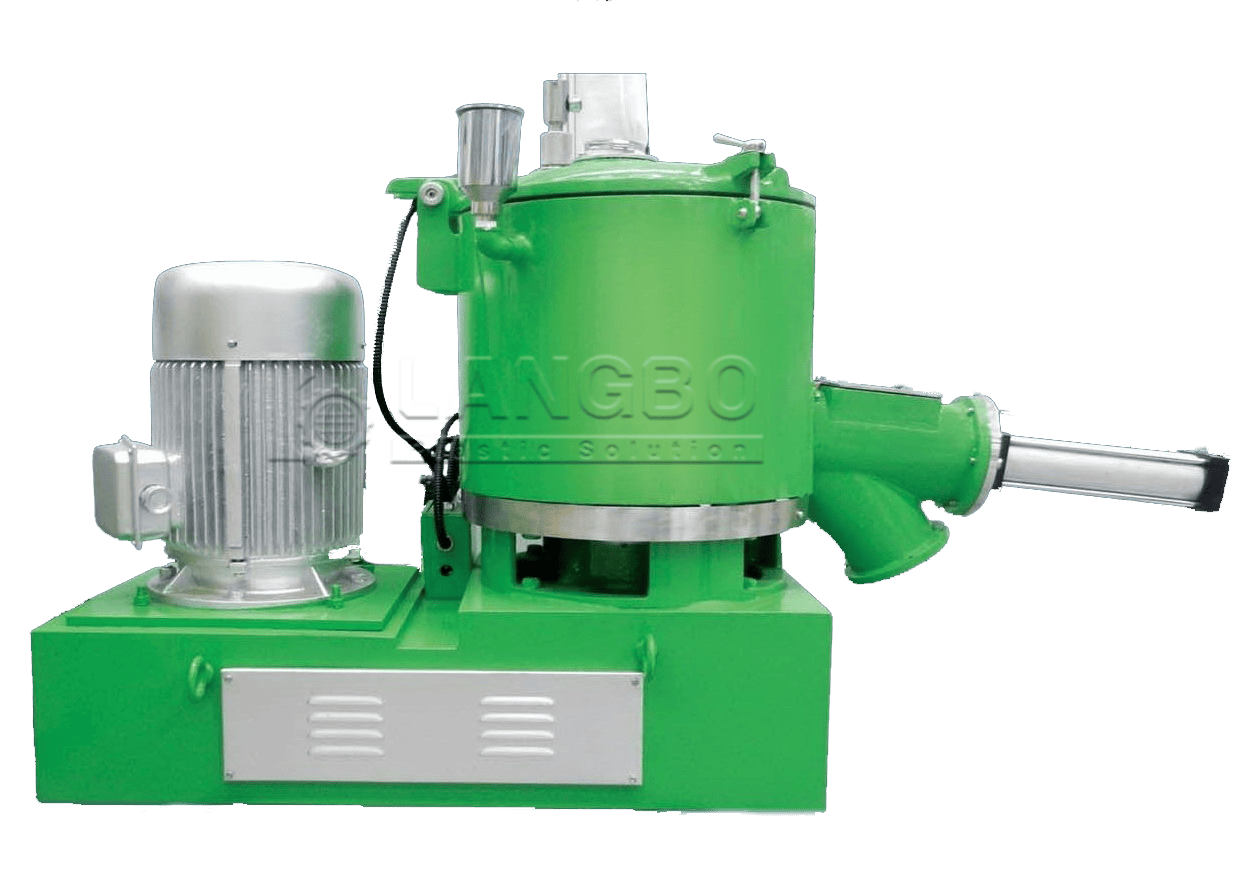

Small mixing capacity 3-10kg/batch. Container volume 10-20L.

Suitable for Laboratory compounding extrusion for testing of formulation.

Heating with electrical or oil as optional.

Heat resistance sealing part for high temperature mixing requirment.

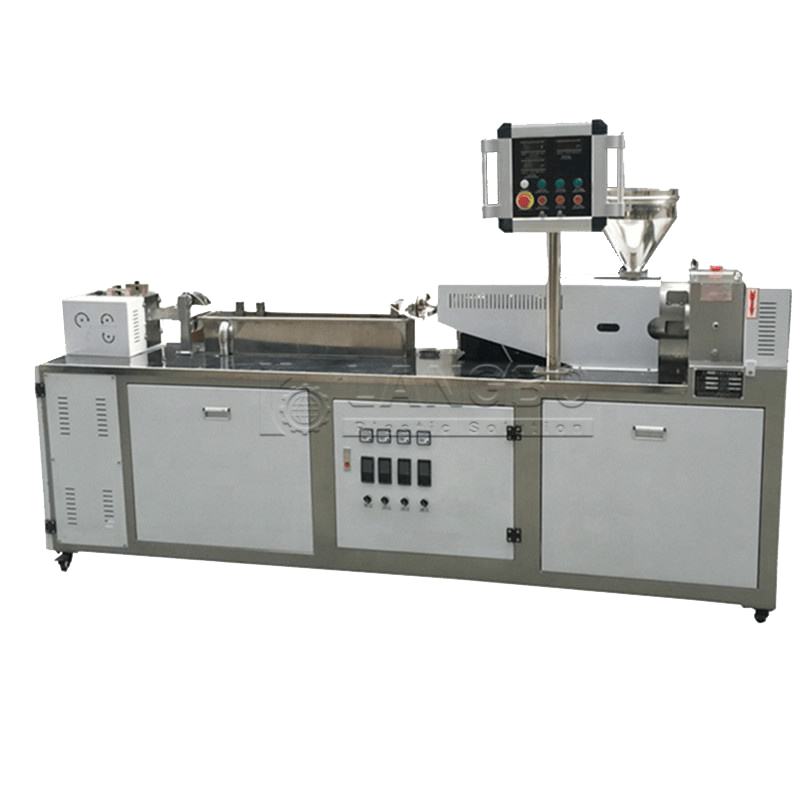

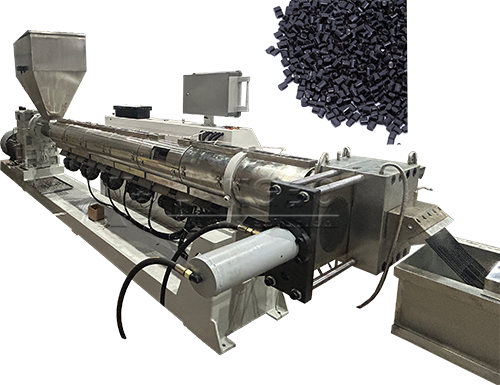

Parallel twin screw extruder for material compounding.

HMI with touch screen or classic buttons.

Production capacity from 10kg/h to 30kg/h.

The whole line can be assembled on one frame or separatly.

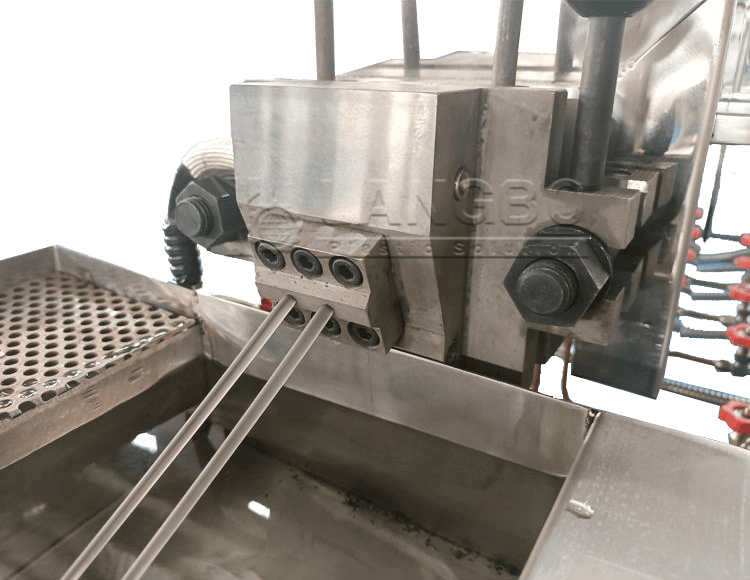

2-4 Strand mold for different capacity

1m-2m water tank based on the extrusion capacity

air knife for drying fixed on the same frame or separatly stand

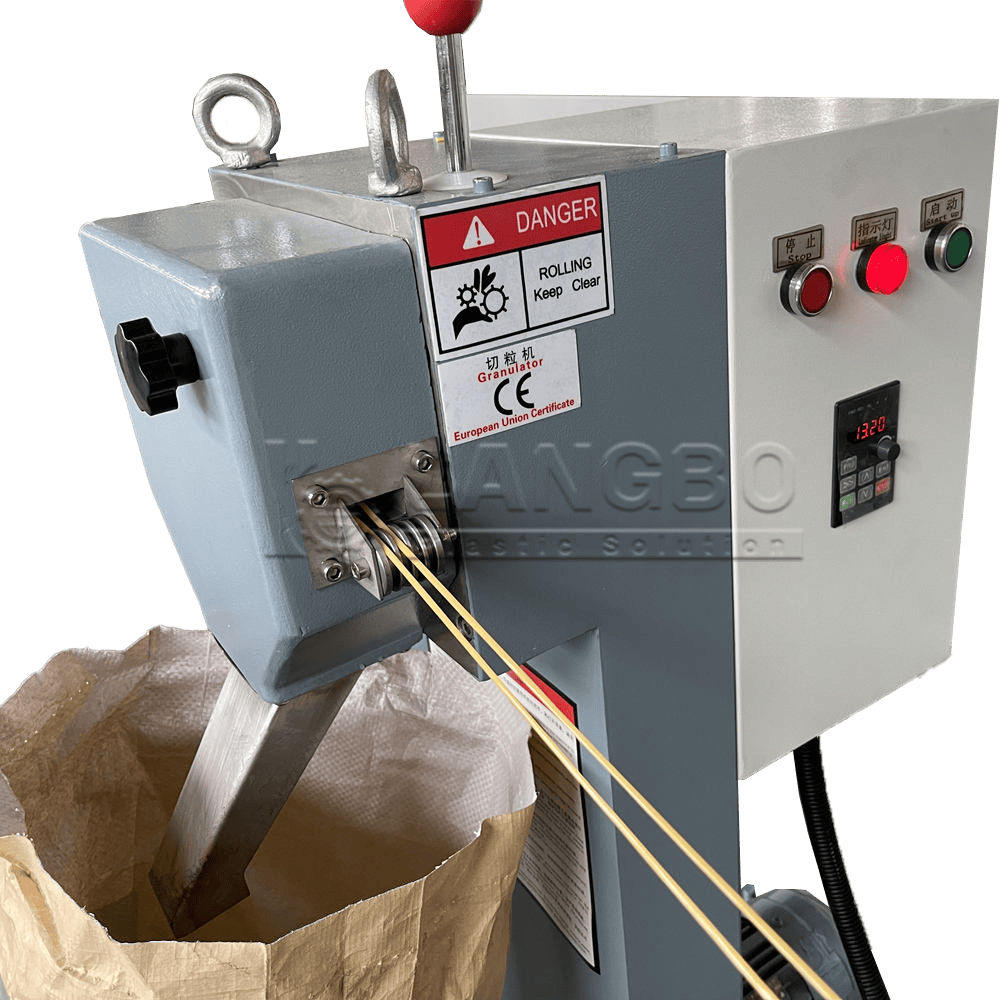

strand cutting pelletizer with frequency inverter for cutting speed control