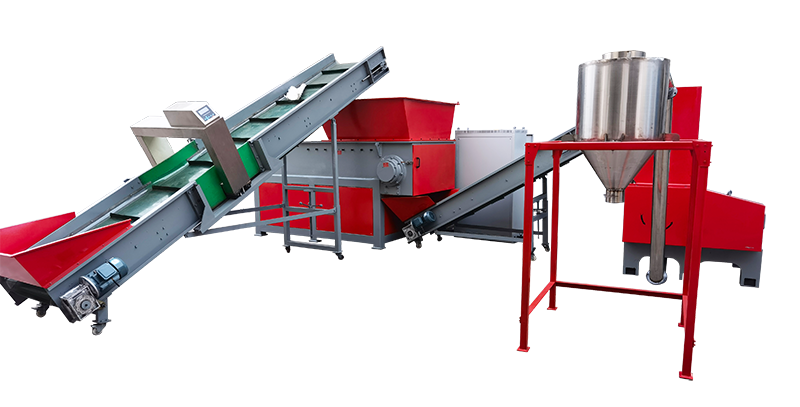

"The shredder operates steadily with consistent output. It handles mixed plastic waste efficiently. The machine structure is solid and easy to maintain."

Highlights

High torque cutting performance for bulky plastic materials

Stable shaft-mounted blade structure for continuous shredding

Wide material adaptability for pipes profiles and thick plastic parts

Optimized chamber design for steady feeding and reduced blocking

Reliable operation with balanced power consumption

Tailored Solution

01.

Rotor and blade configuration for rigid plastic shredding

Based on the customer’s material characteristics including thick pipes and rigid plastic scraps the shredder was configured with a reinforced rotor and optimized blade arrangement. The shaft-mounted knives ensure controlled cutting instead of impact crushing resulting in stable output size and reduced vibration during operation

02.

Motor selection matched to material thickness

According to the required throughput and material hardness the motor power and rotation speed were selected to achieve sufficient cutting torque while maintaining reasonable energy consumption. This setup supports long time operation without overload

03.

Controlled discharge and stable operation

The discharge opening and cutting configuration were adjusted to achieve consistent particle size and stable material output. This setup helps maintain smooth operation during continuous shredding while reducing material accumulation and manual intervention.