Thread specifications can be adjusted by changing tools, adapting to pipes of different diameters (e.g., 10mm-250mm) and materials (PVC, PE, PP). Capable of processing various thread types, such as tapered, cylindrical, Whitworth (compliant with DIN 2999), trapezoidal (compliant with DIN 4925), gas threads, etc..

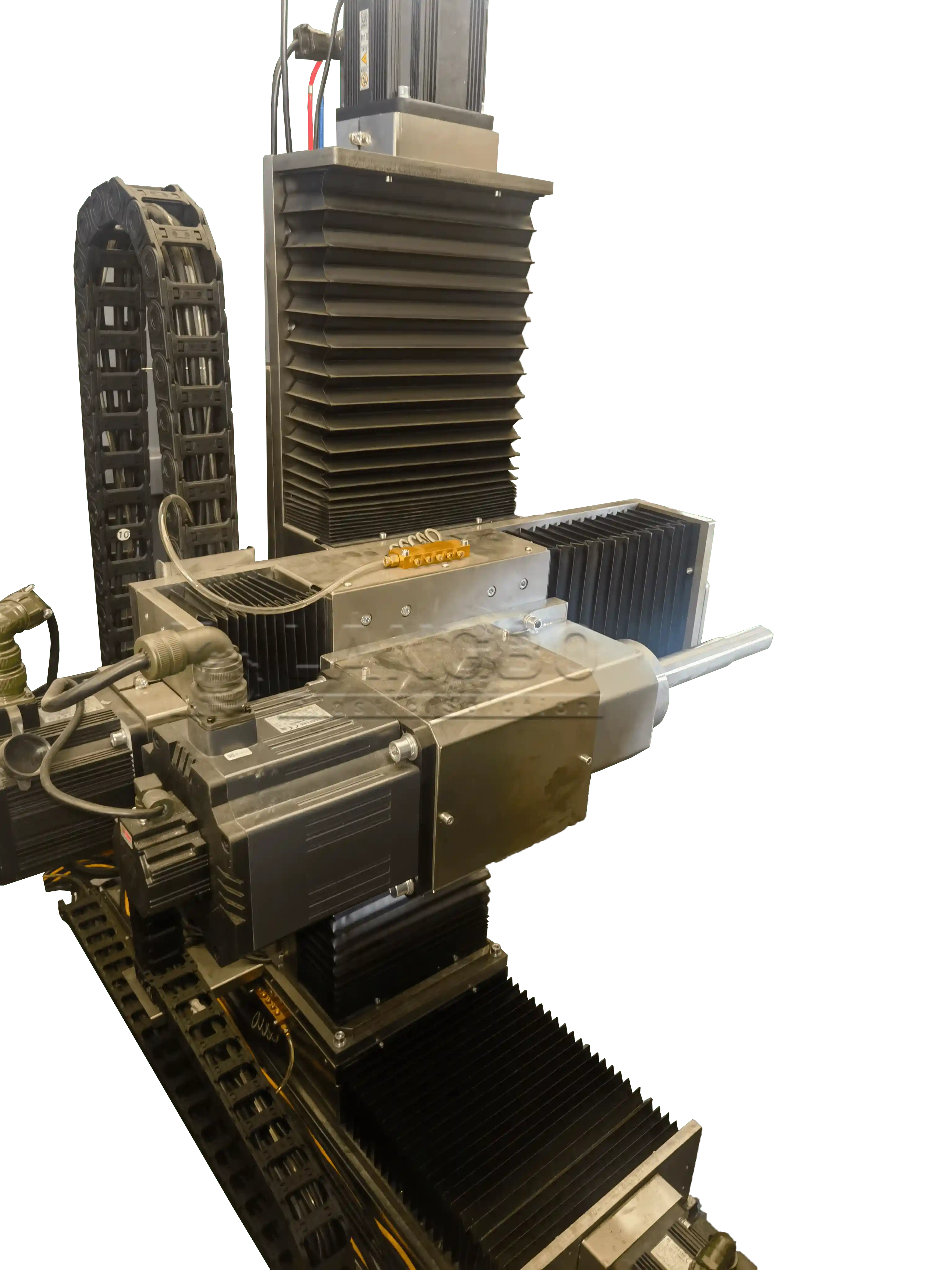

The high precision of the executive parts such as guide rail and servo motor keeps the repeatability of threading process, so that the interchangeability and high sealing quality will be ensured. High standard executive parts can help with an easy daily maintenance and long working time, this is the key point for a good machine quality

Pipe transportation device can take the pipe from extrusion line to the CNC threading machine.

Pipe storage position helps the CNC threading machine working off-line.

It means the operator only put the pipe into storage position and pipes will be transported automatically and making thread one by one.

Features a Human-Machine Interface (HMI) for intuitive parameter setting and operation. The equipment usually includes sealed designs, sound insulation systems, and safety protections.

Simple design working like lathe machine

the to be threaded pipe end is clamped at the machine and pipe rotates for thread making

cost effective design and low automatic grad