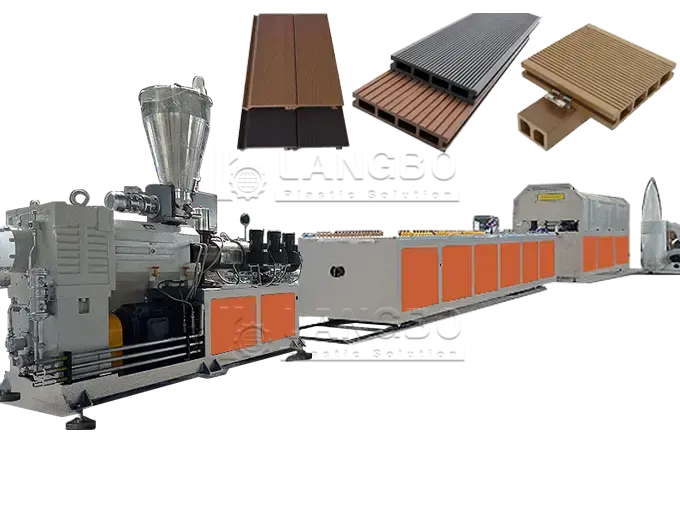

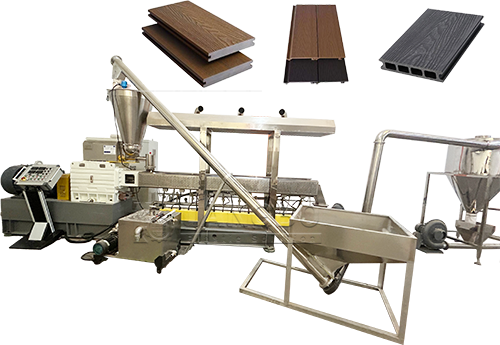

Due to the feature of Extrusion, the conical twin screw extruder with the model SJSZ65/132 is the suitable extruder

Based on our expericece, a enlarged barrel will be used on the extruder

Single screw extruder can be used for co-extrusion with functional surface layer

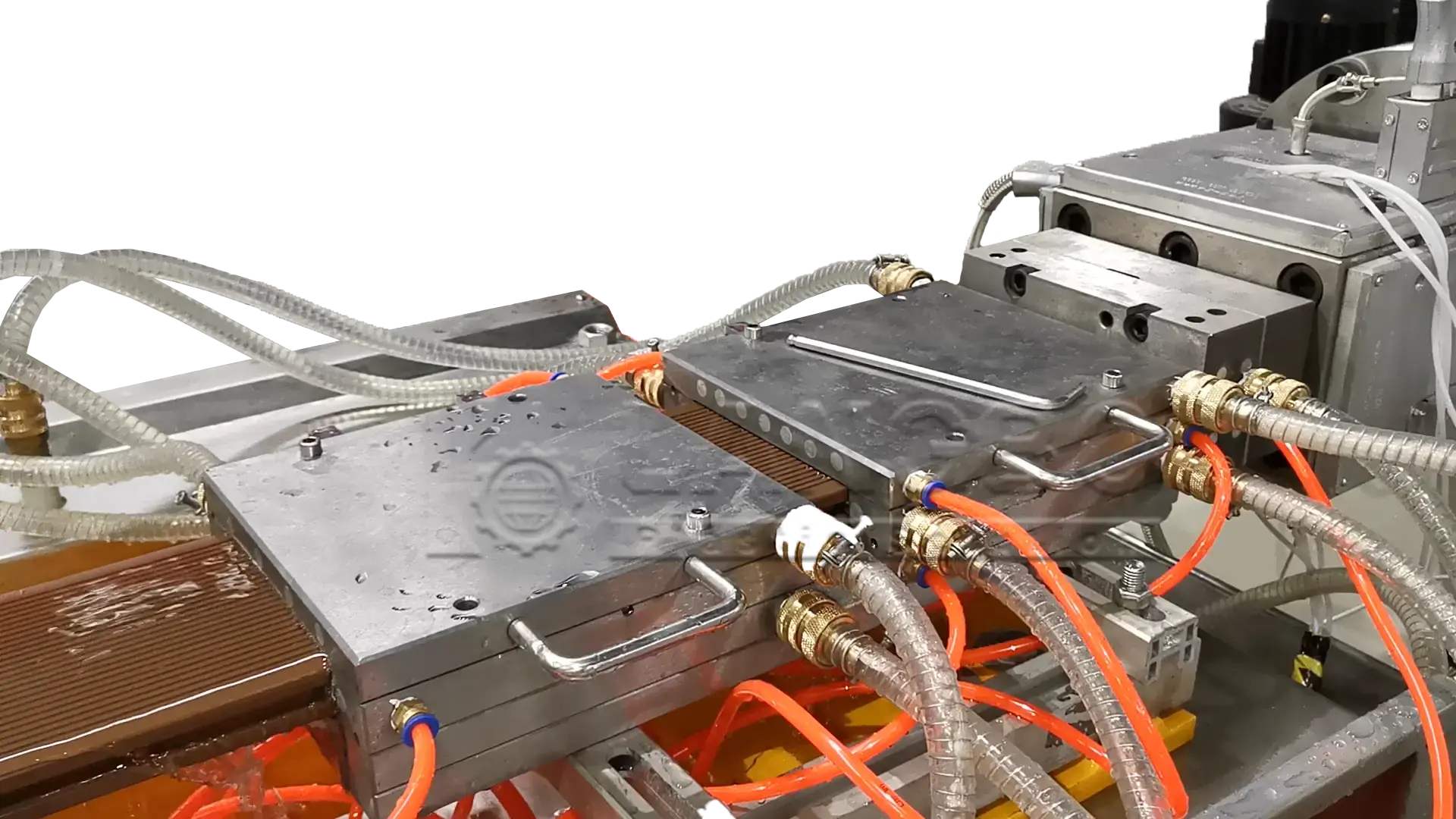

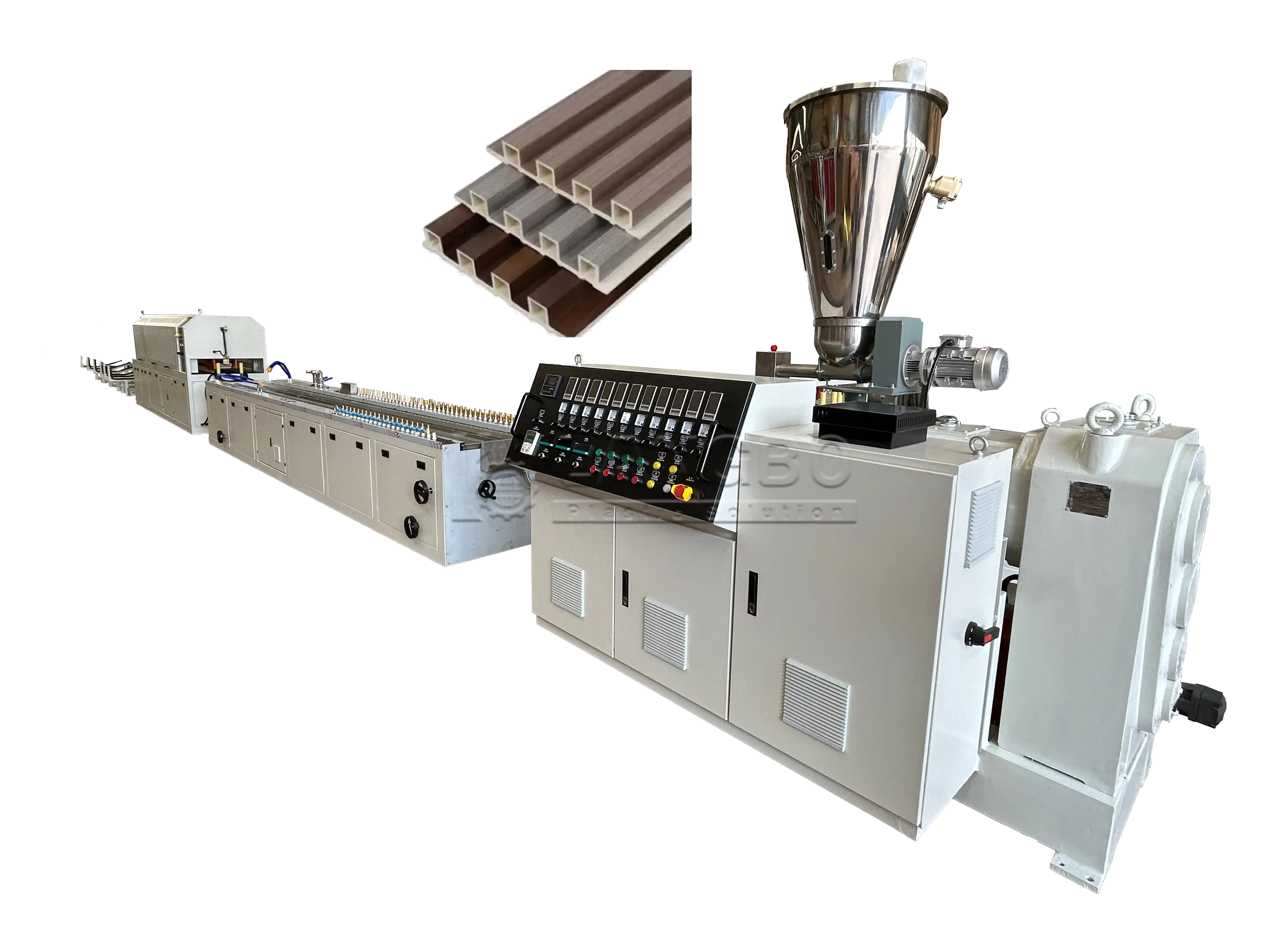

High precise mold manufacturing and High quality mold steel ensure a reliable mold system

The mold helps a high extrusion speed and stable production

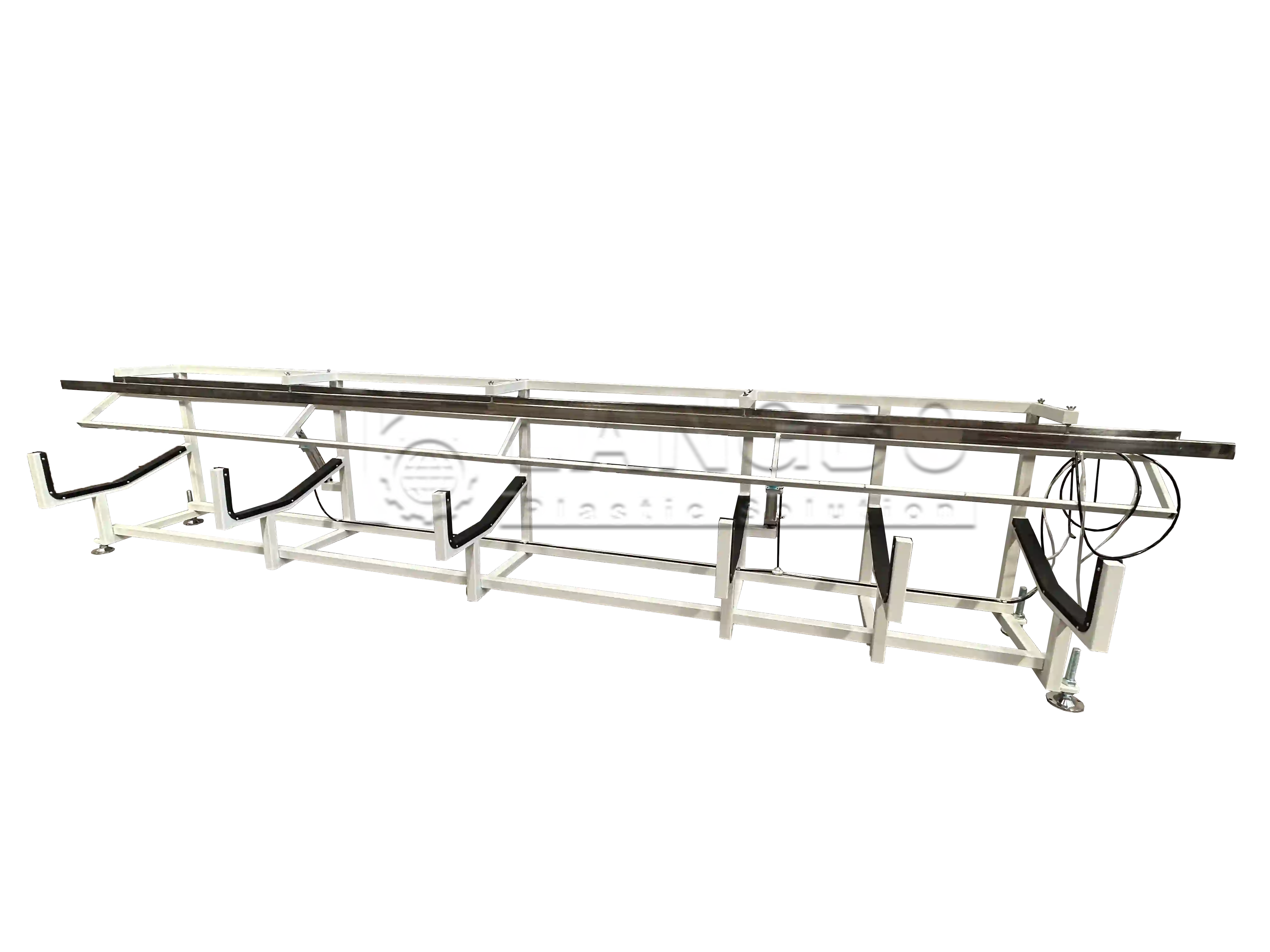

The cooling table offers vacuum and cooling water for the calibrators.

The haul-off will be integrated on the cooling table.

It helps a short lenght of the whole line and guarateed the production result.

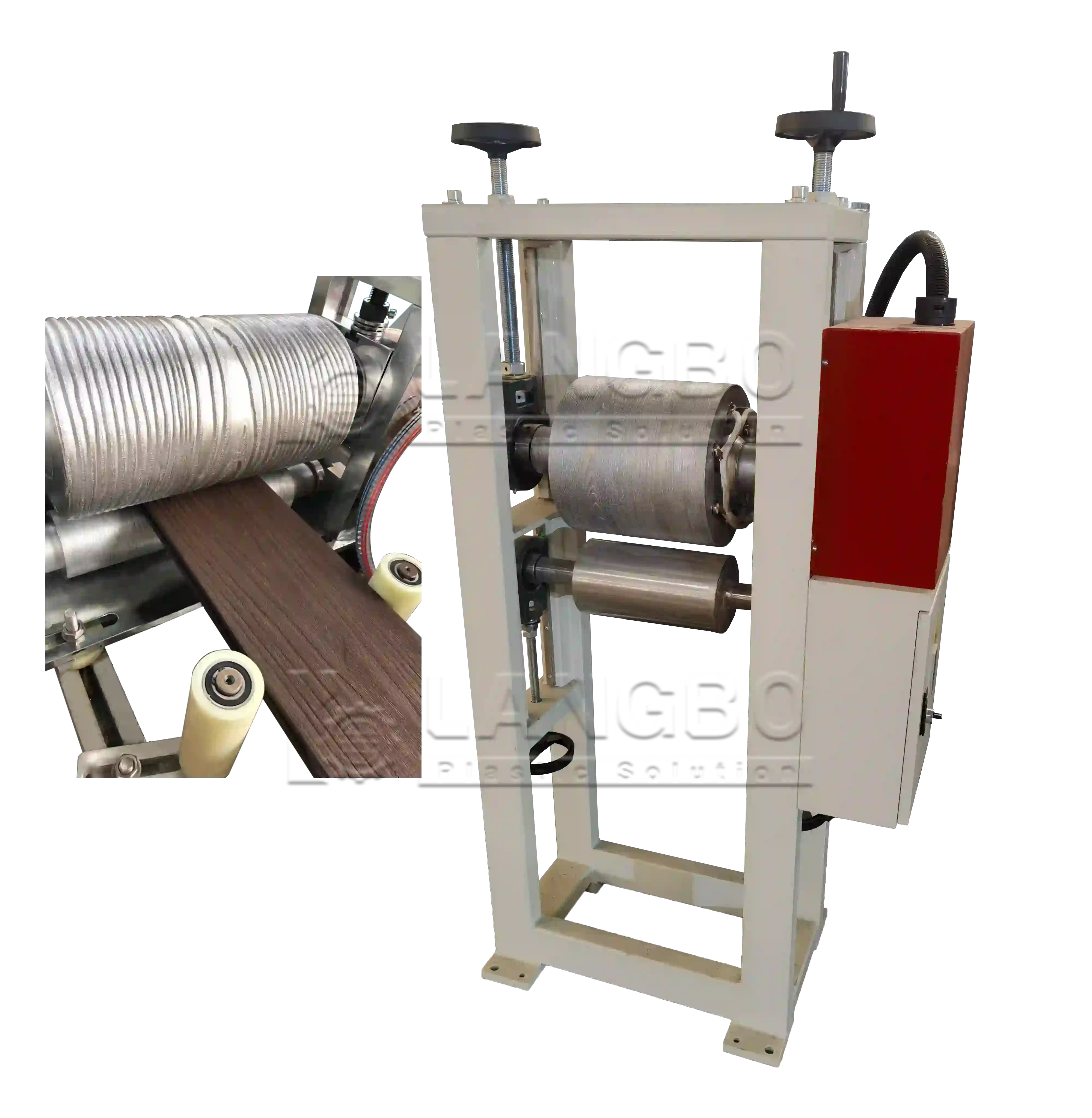

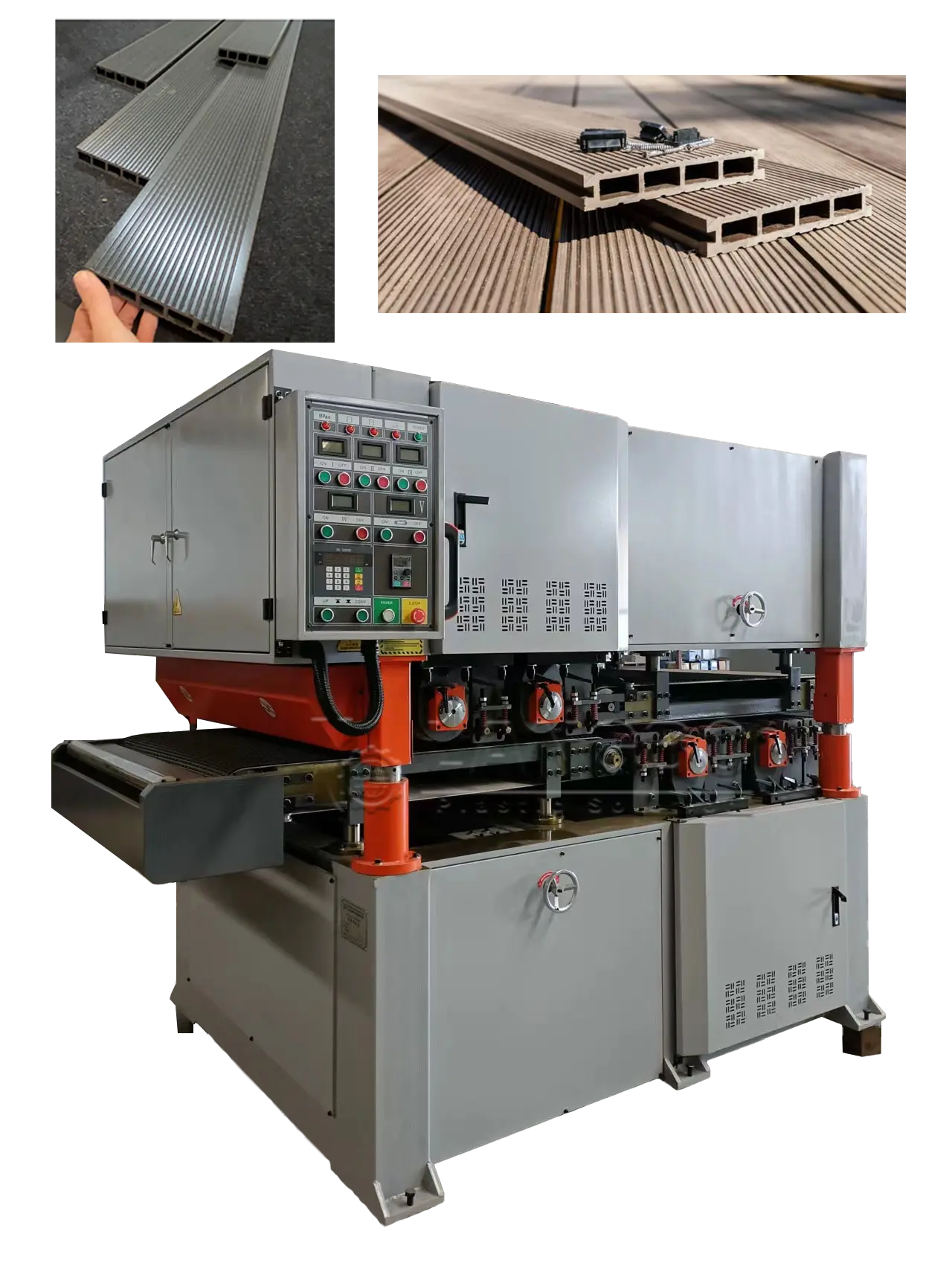

The online embossing forming the surface structure directly after the production extrusion.

It can be fixed on the cooling table.

The Product will be cut after getting a set length. The length is counted by encoder. There will also be a limit switch on the pneumatic stacker, when the product touch the switch, the cutter will running for a production safety.

Dust collector is connected with cutting machine.

Stacker unloads the products after a few seconds of cutting, the delay time can be set on the PLC of cutting machie

Sanding machine makes the surface more rough and more firction in the application for better walking safety