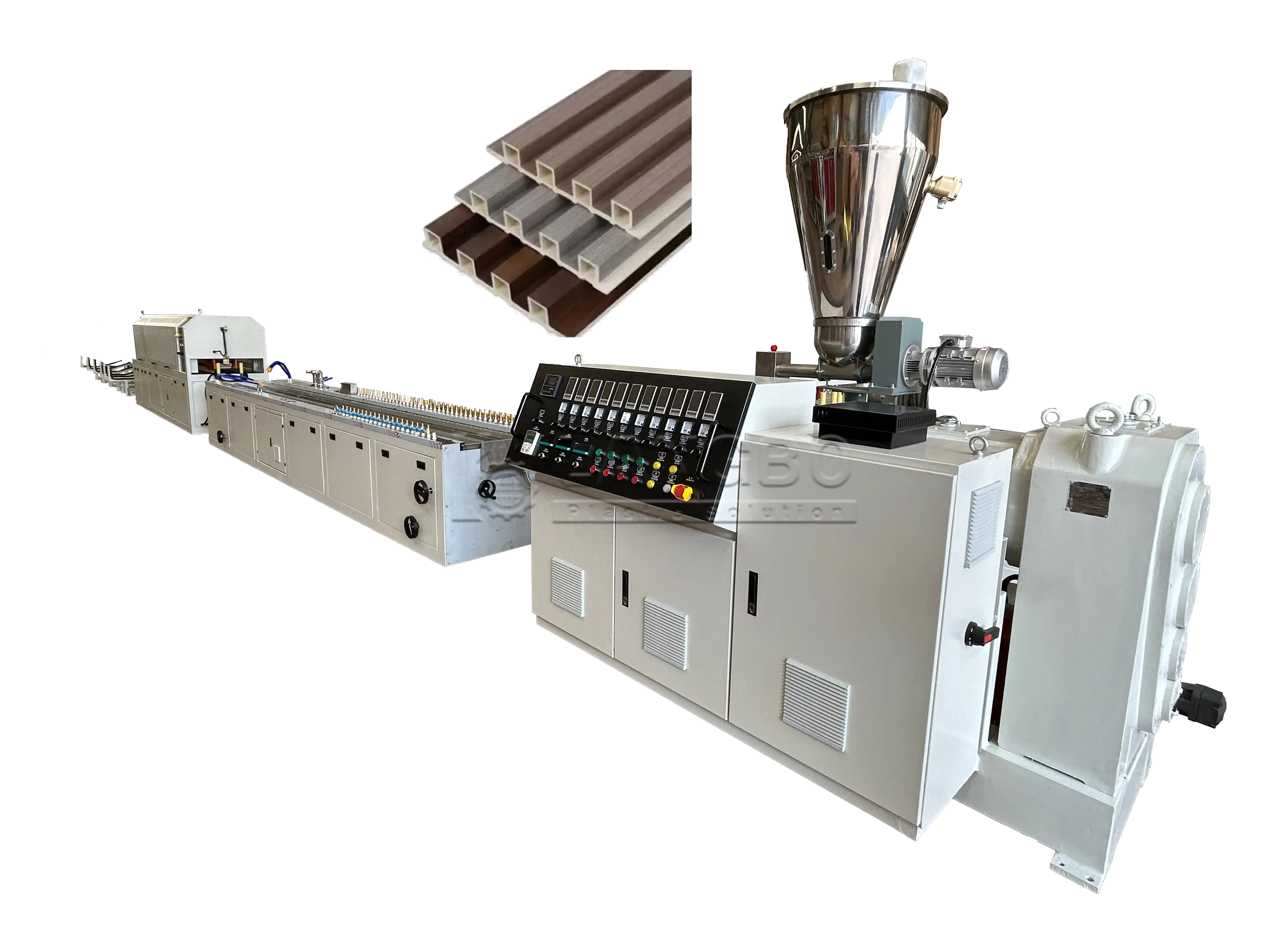

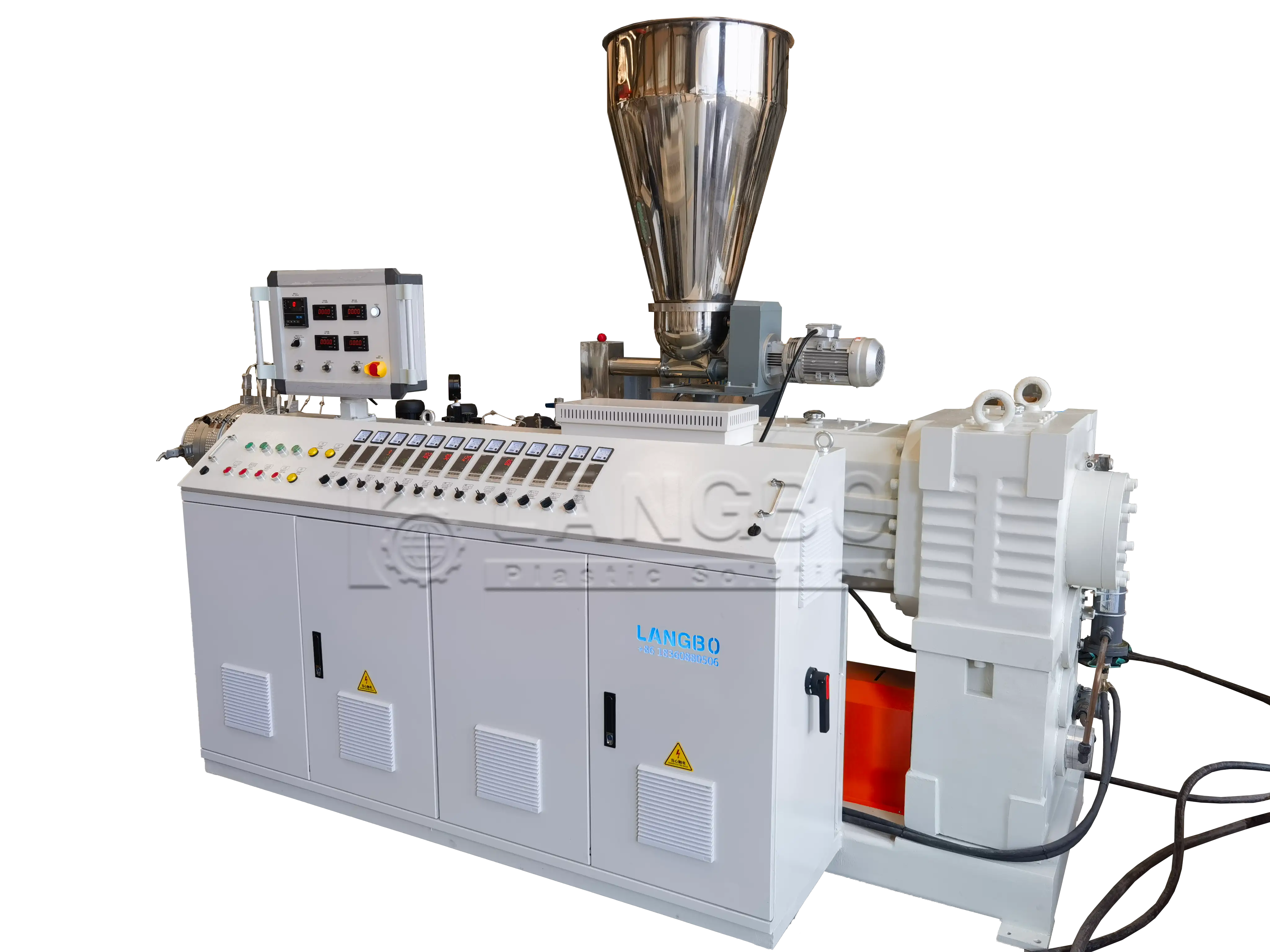

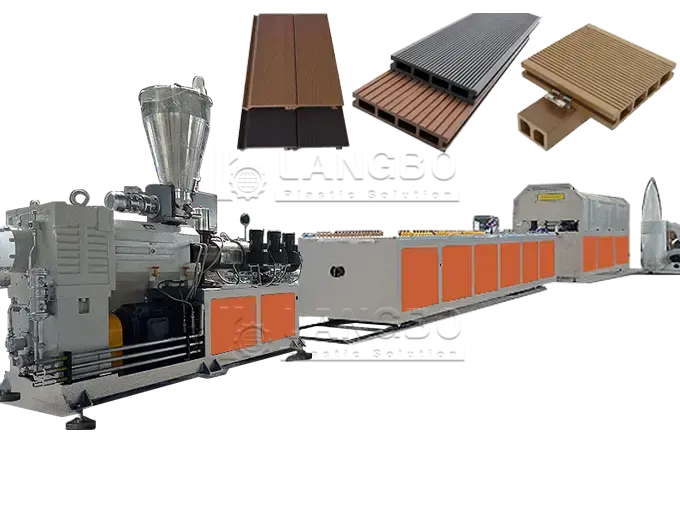

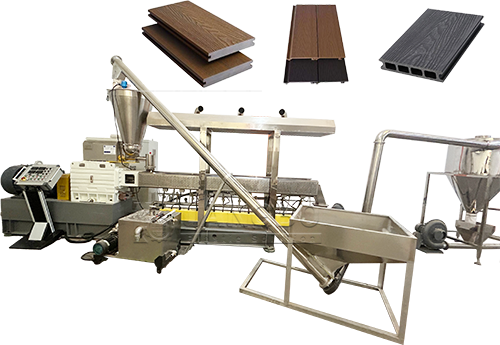

Various combination of extruders to fit customized extrusion demand

Special design for gentle processing such as extrusion of PVC

Permanent magnet synchronous motor for reducing 10%-20% energy consumption comparing with DC or AC Motor

Siemens Motor and ABB Frequency inverter for optional for worldwide after-sales service

Operator oriented operation logic for clever and easy operation during production

Touch screen (optional) for an integrated information management and easy operation

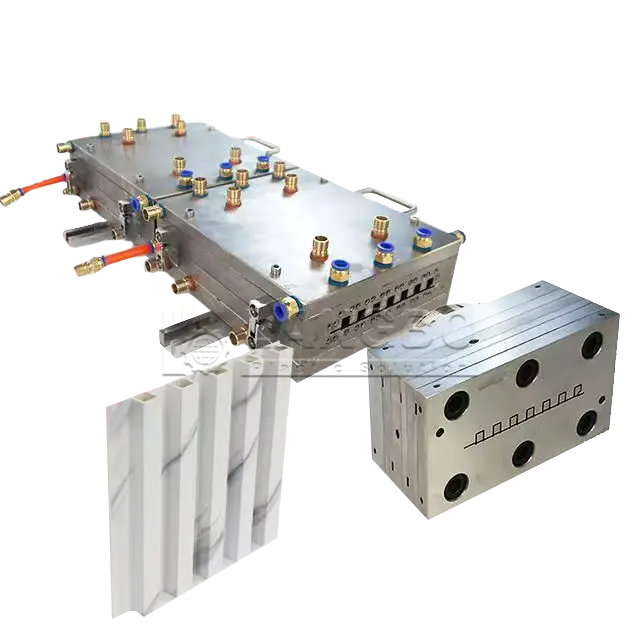

Mould matching based on size of profile and extrusion volume

High flow performance due to optimized channel design

Manufactured by advanced machine tool with high precision

High quality material for mold and calibrator

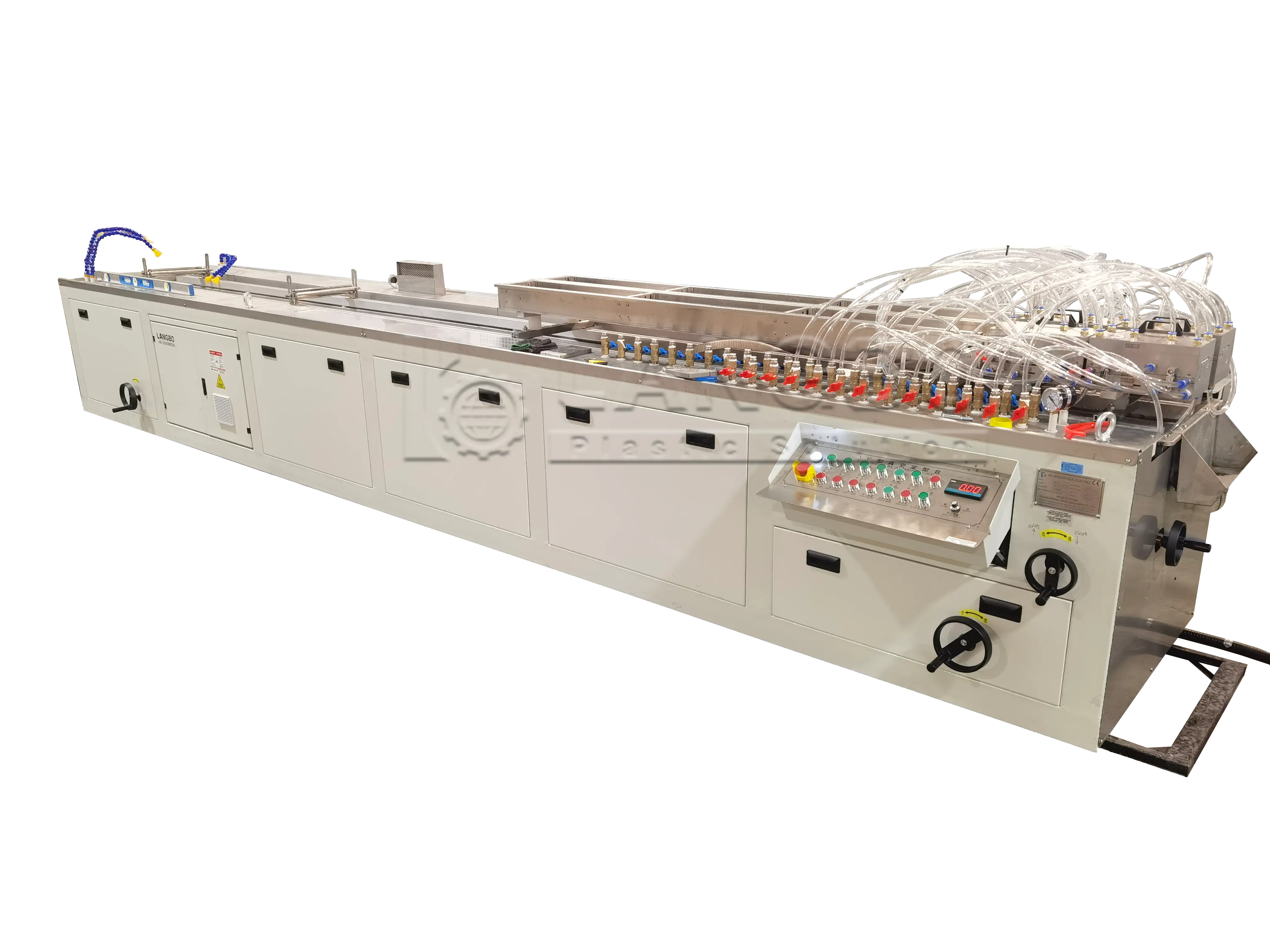

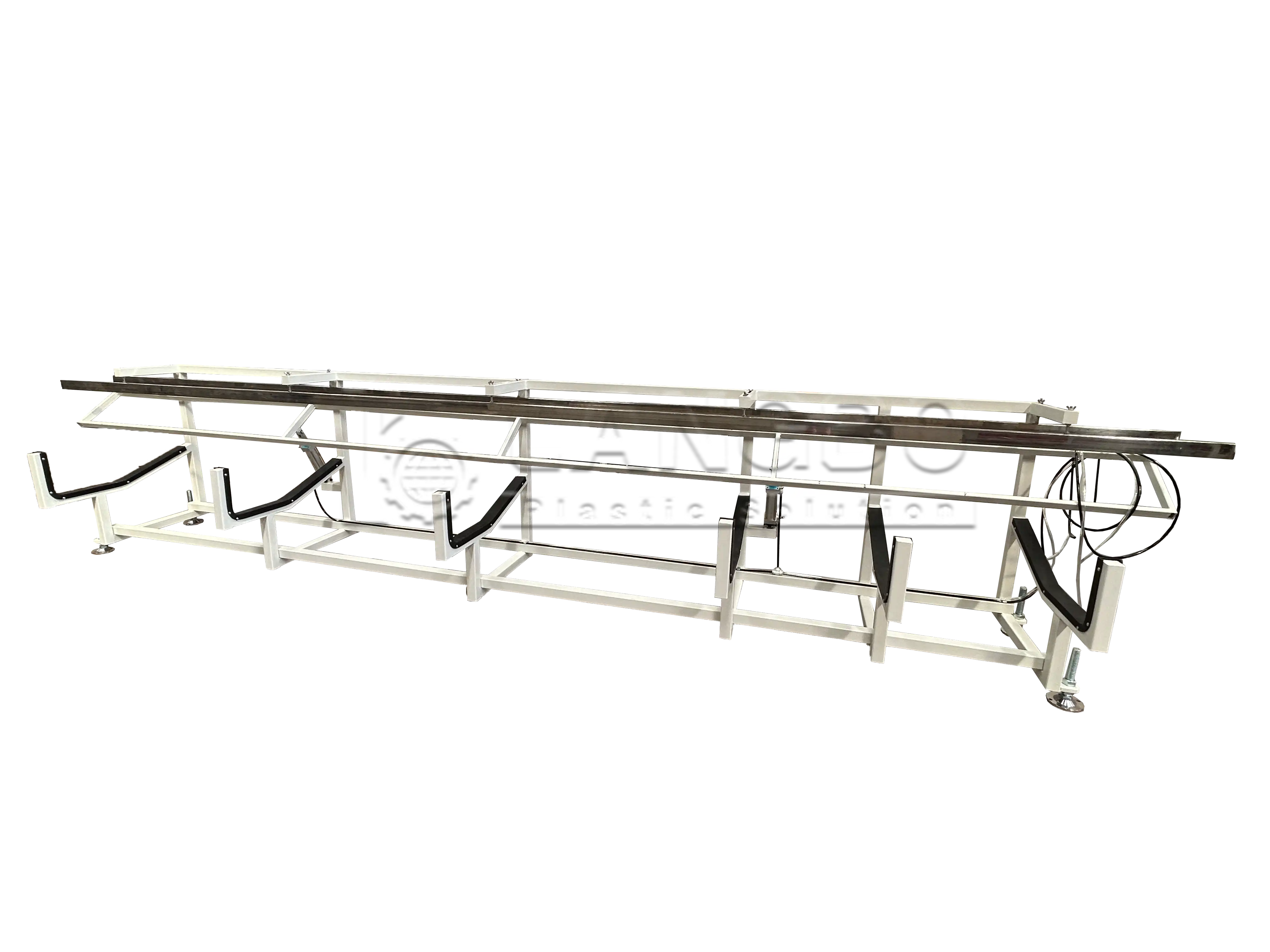

Sturdy steel frame and high-quality body material like SUS 304 stainless steel

Multi-dimension position adjustment system

Operation optimized water circuit system for energy saving

Optimized layout of valves for vacuum and water for rapid shaping and cooling

Easy operation and synchronization for controlling the extruder

Based on features of products the haul-off and cutting can be separated or combined

Sufficient hauling force with even force distribution along caterpillars

Hauling Rubber easy replace and spare part delivered for free

Highly Synchronized hauling for stable quality of products

Pneumatic pressure for easy adjustment and product protect

Stable stacker structure and pneumatic unloading, Width of stacking panel designed by prodcut

Reliable manufacture technology and high-quality part ensure a long term stable production