“The spiral pipe line operates steadily and produces consistent pipe quality. The forming accuracy meets our requirements, and the line is easy to adjust during daily production.”

Highlights

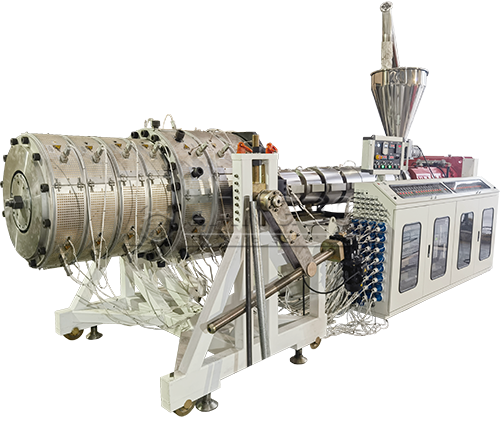

Stable extrusion for spiral structured plastic pipes

Uniform pipe wall thickness with consistent spiral forming

Reliable calibration and cooling for dimensional stability

Flexible configuration for different pipe diameters

Continuous operation suitable for long production runs

Tailored Solution

01.

Extrusion and spiral forming matched to pipe structure

Based on the customer’s product design and pipe diameter range, the extrusion unit and spiral forming mould were selected to ensure stable melt flow and accurate spiral geometry. The forming structure supports consistent pipe shape during continuous production.

02.

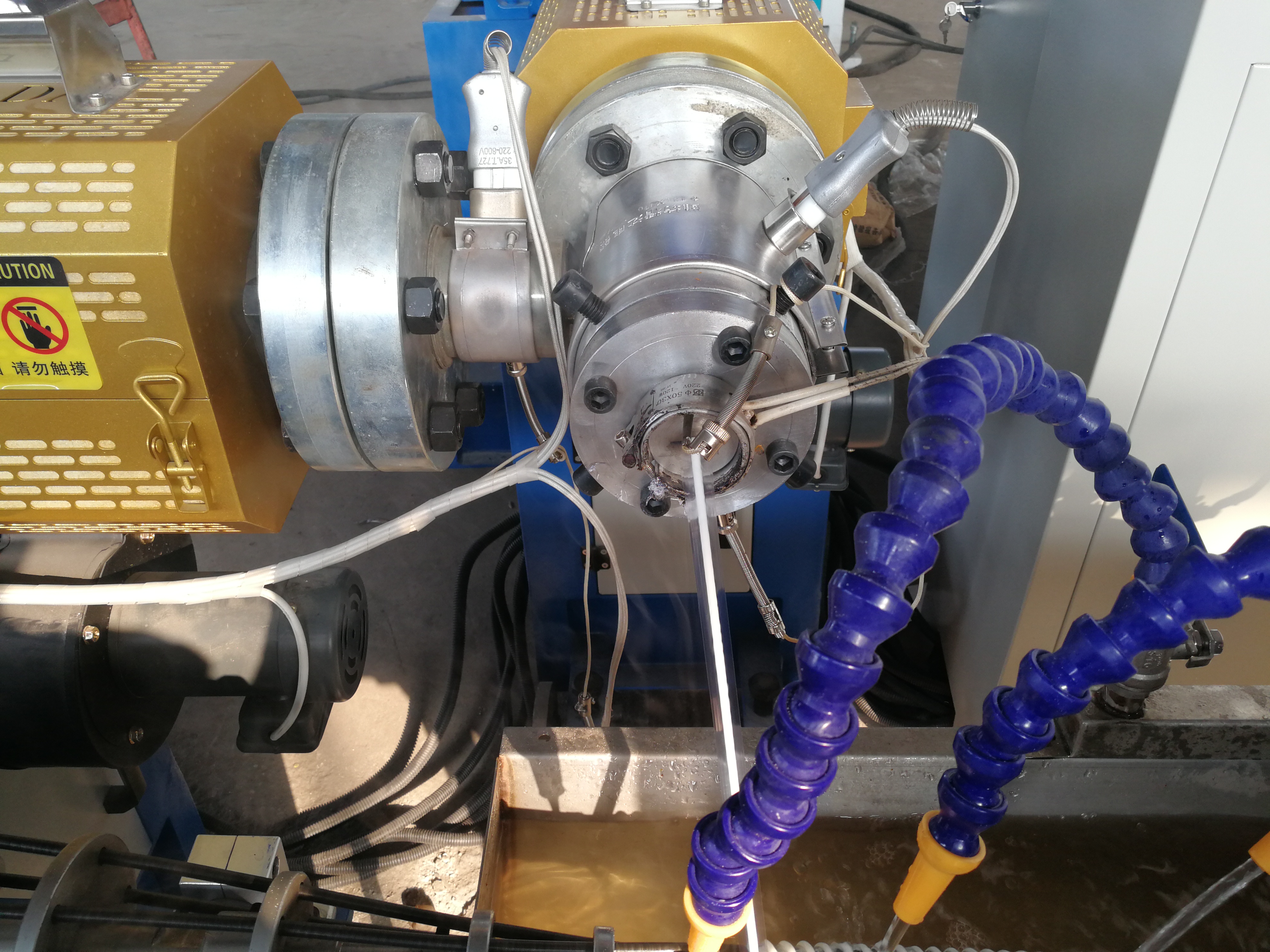

Calibration and cooling adjusted for spiral pipe characteristics

The calibration and cooling section was configured to provide gradual and uniform cooling along the spiral pipe profile. This helps maintain dimensional accuracy and reduces deformation caused by uneven heat release.

03.

Controlled discharge and stable operation

The haul-off speed and cutting parameters were adjusted to match the extrusion output, ensuring smooth pipe transport and consistent cutting length. This configuration supports stable operation and reduces manual adjustment during production.