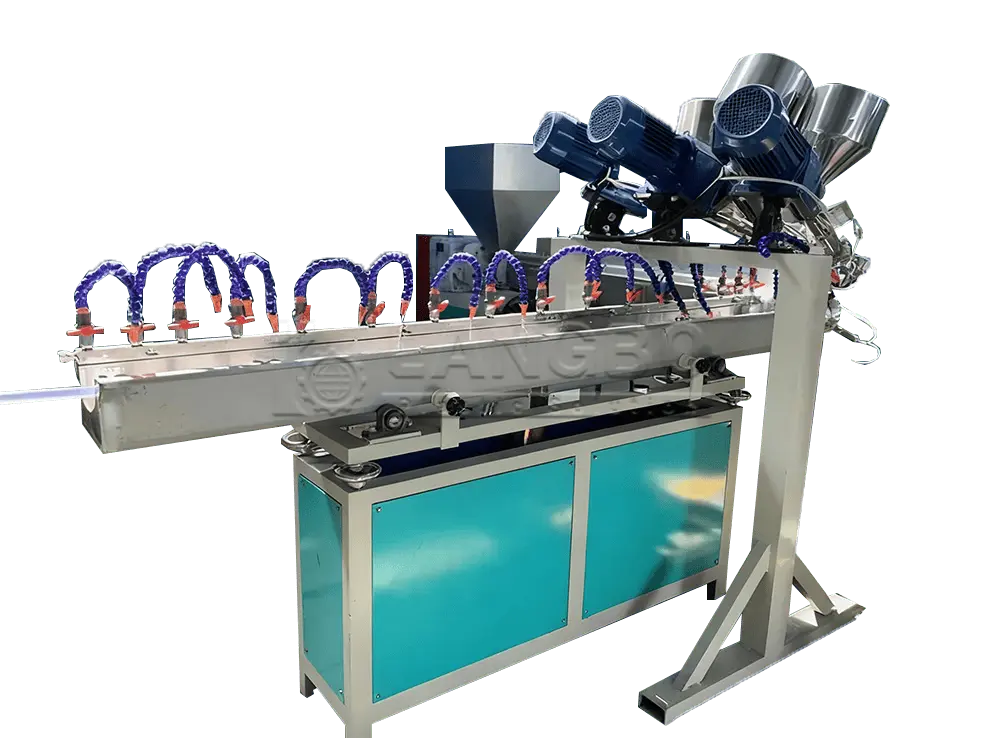

SIngle screw extruder for inner hose layer extrusion with PVC granules

Air is connected with the mold for blowing so that the pipe will keep the shape

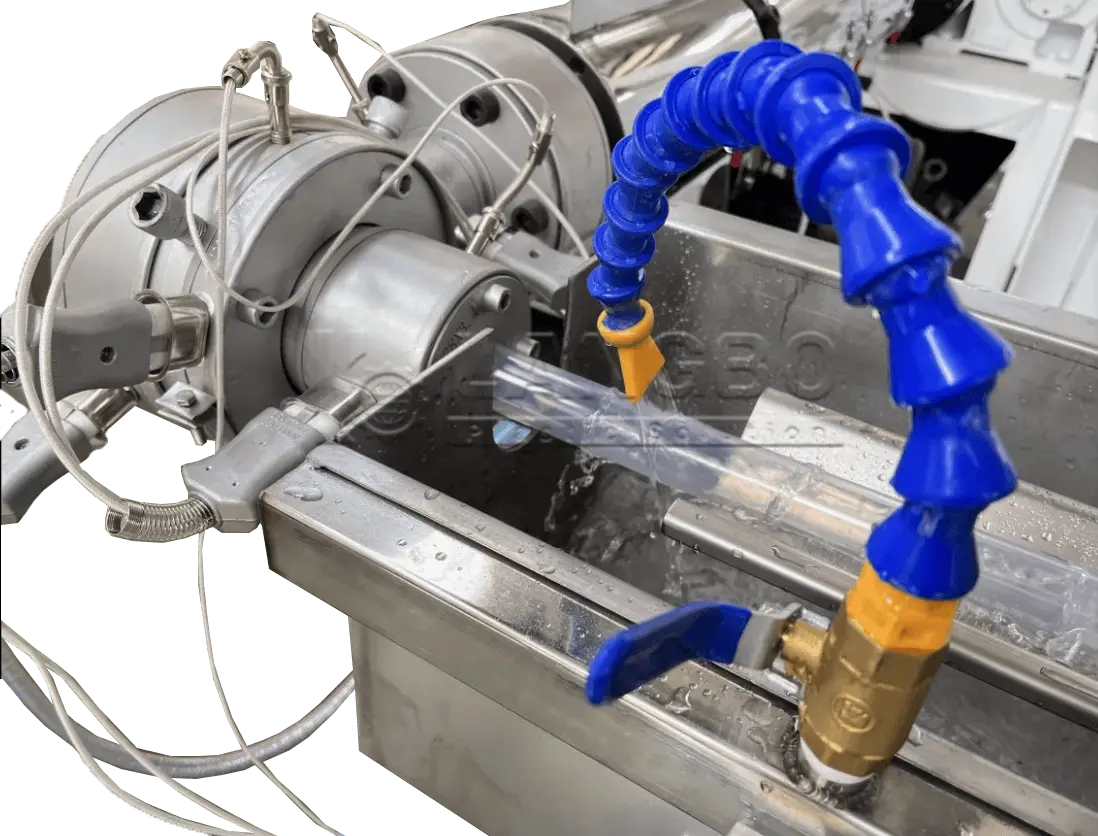

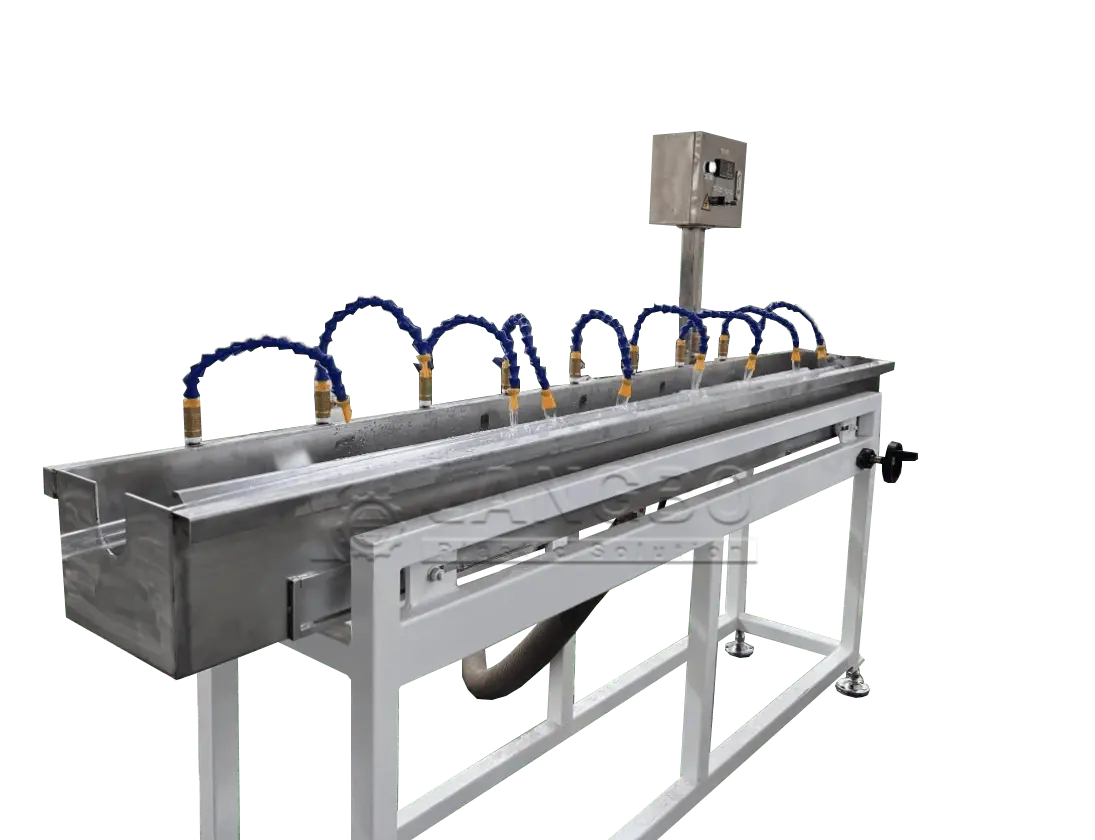

Water tank for inner layer hose cooling

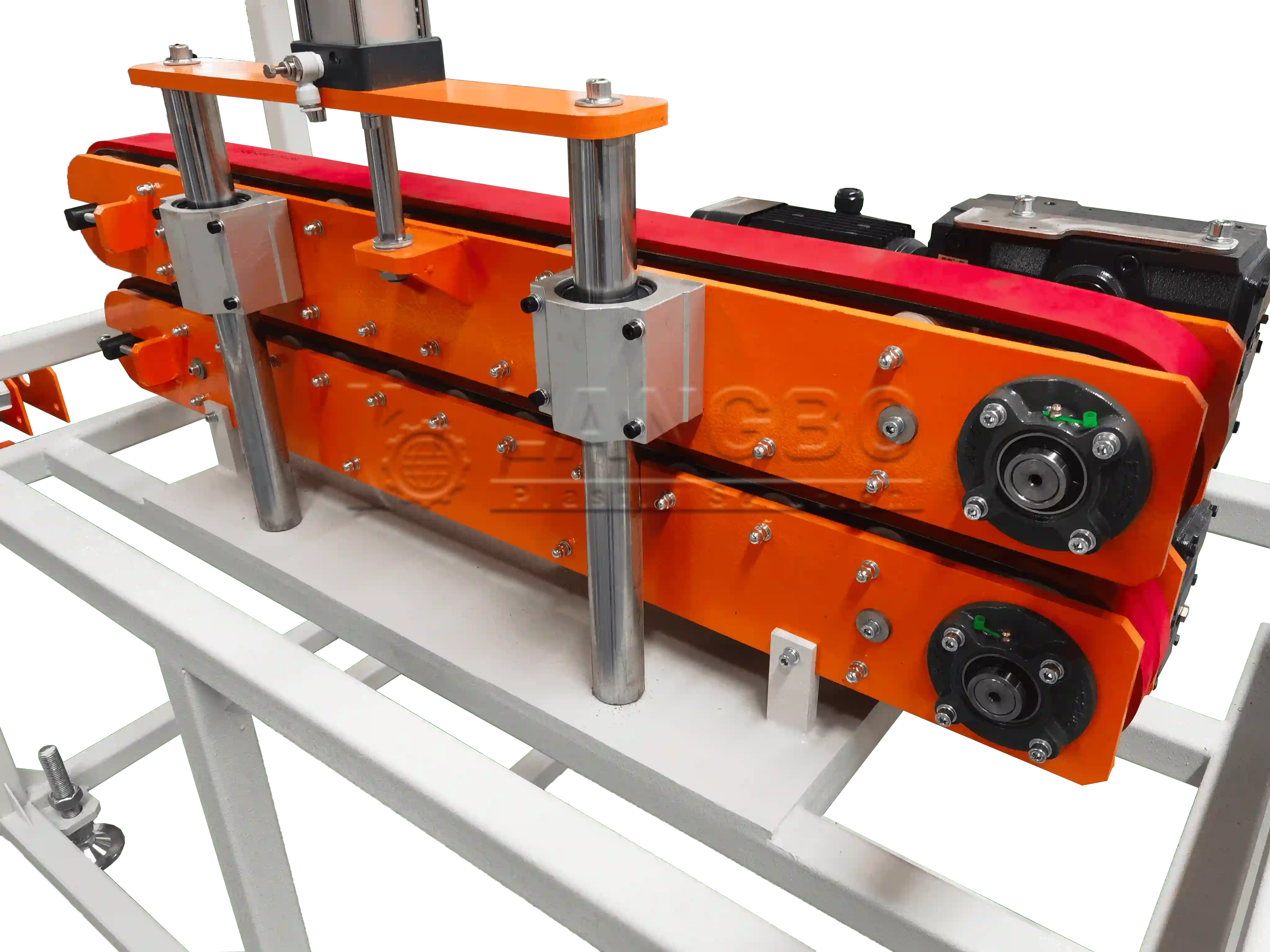

Belt haul-off for inner hose layer

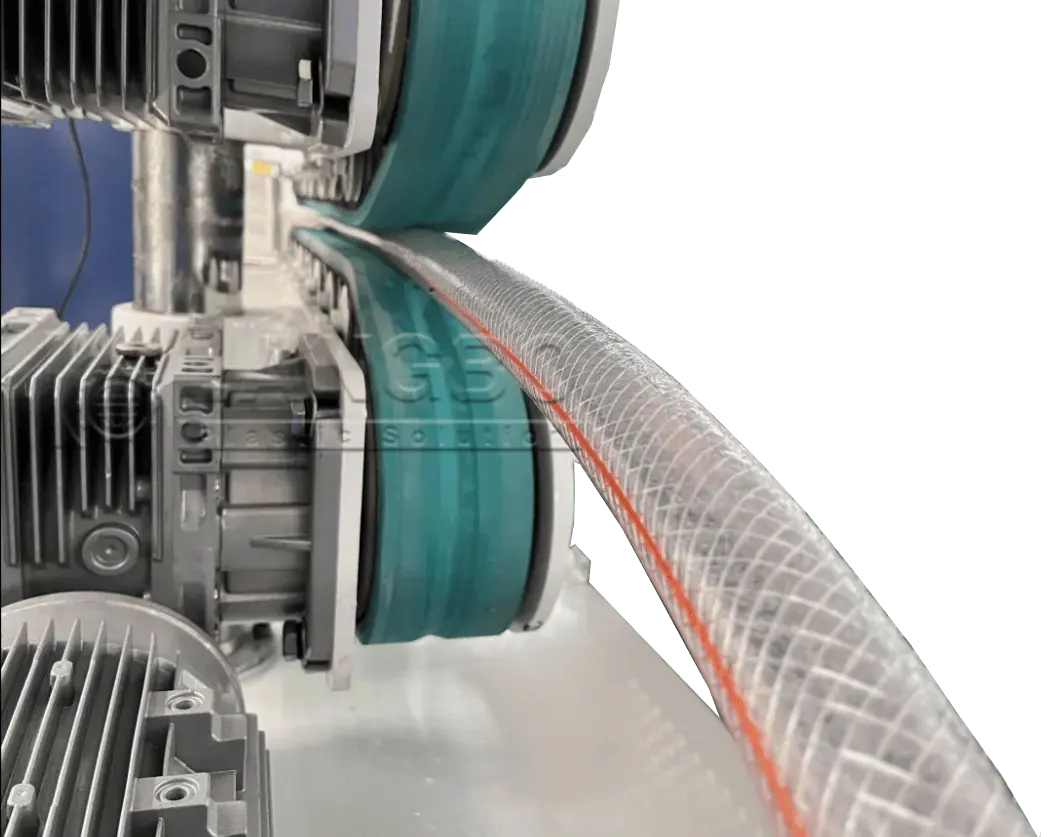

High speed fiber draiding with double disks

The oven heats the inner layer and braid layer for preparation of outer layer extrusion

With the second extruder the outer layer will be extruded.

Based on the market requirment the strip line could be from one to three strip.

The finished pipe will be pulled at the second stage haul-off machine.

Based on the market requirement, the hose can be coiled manual or automaticly