Poland

HDPE Corrugated Pipe Extrusion Line

The corrugated pipe line runs steadily and efficiently. The pipes produced have uniform corrugations, excellent flexibility, and consistent wall thickness.

Highlights

Uniform corrugation shape and wall thickness

Strong mechanical properties with high flexibility

Suitable for long-distance and continuous production

Energy-efficient and low maintenance

Tailored Solution

01.

Extruder

A single-screw extruder provides stable melting and uniform material flow, ensuring reliable output for high-speed corrugated pipe production.

02.

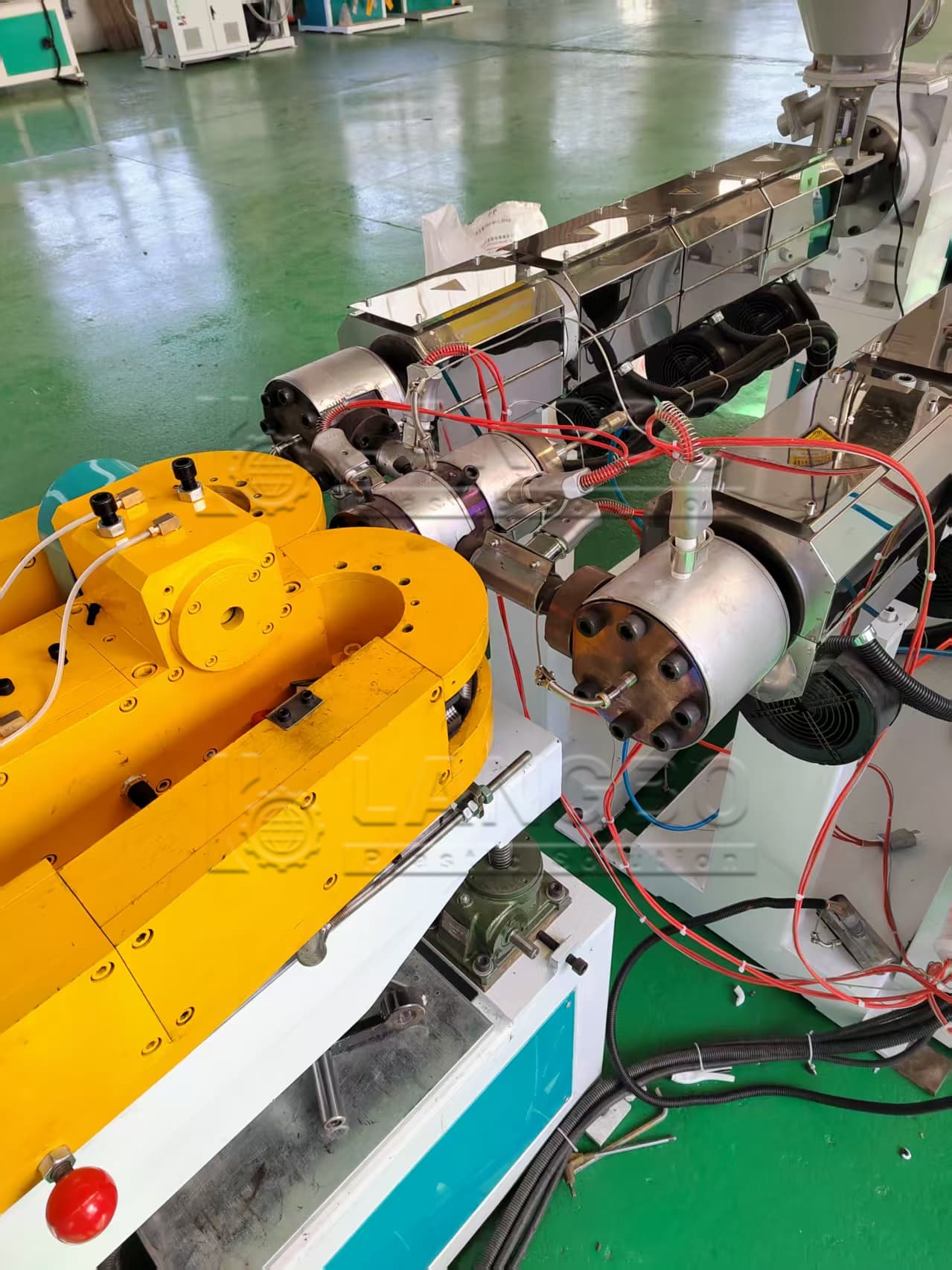

Mould

The corrugation mould forms uniform corrugations with precise wall thickness, maintaining pipe strength and dimensional accuracy.

03.

Forming Machine

The forming machine shapes the corrugated pipe profile consistently, with adjustable settings to accommodate different pipe diameters and wall thicknesses.

04.

Coiler

The coiler collects finished pipes efficiently and neatly, preventing deformation or damage during winding.